Programmable Logic Controllers (PLCs) are the backbone of modern industrial control systems. From assembly lines to energy grids, they enable automation, precision, and reliability. Among the most trusted names in this space is Allen-Bradley, a brand of Rockwell Automation. Known for their engineering quality and adaptability, Allen-Bradley PLCs are widely used across various industries, including manufacturing, food and beverage, oil and gas, and more.

This guide explores the different types of Allen-Bradley PLC models, their features, use cases, and selection tips, helping you choose the right one for your industrial automation needs.

What is a PLC?

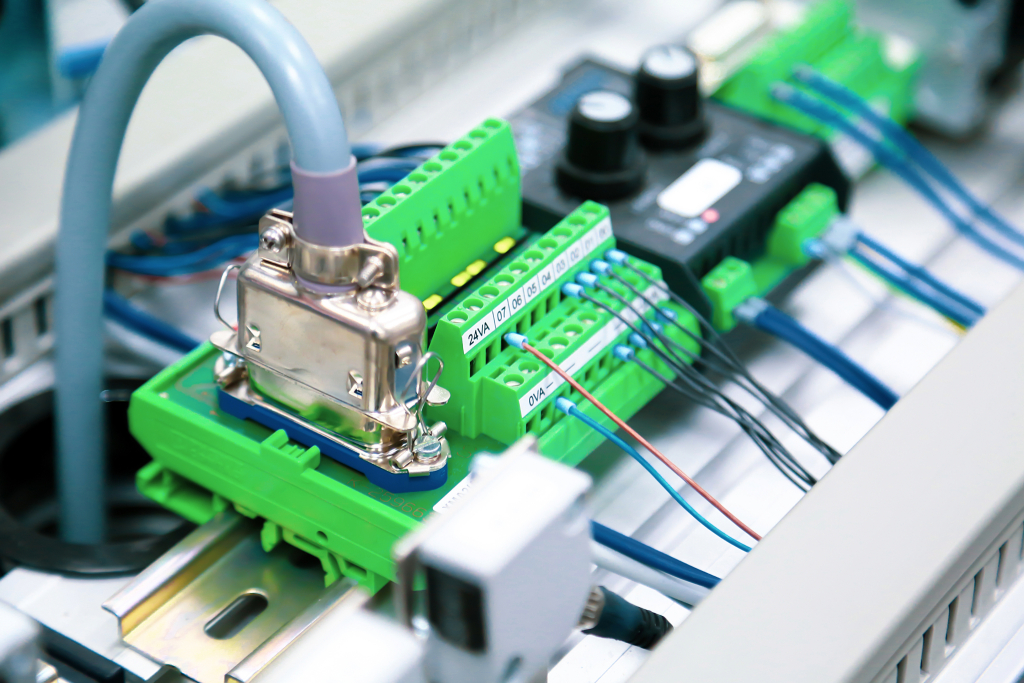

A PLC, or Programmable Logic Controller, is a compact digital computer designed for industrial automation. Unlike traditional computers, PLCs are built to operate in harsh environments and provide real-time control over mechanical processes.

PLCs receive input signals from field devices, such as sensors or switches, process logic based on programmed instructions, and then send output signals to actuators, motors, or indicators. Their main advantages are:

- Rugged construction for factory environments

- Real-time processing

- Flexible programming options (ladder logic, function block, structured text)

- Long operational life

Whether it’s regulating temperature, managing conveyor belts, or coordinating robotic arms, PLCs deliver control with high accuracy.

About Allen-Bradley

Allen-Bradley is a flagship automation brand of Rockwell Automation, a global leader in industrial technology. Known for its high-performance control systems, Allen-Bradley has earned its place across industries due to product reliability and flexibility.

From compact logic controllers for basic machines to high-performance systems for plant-wide control, Allen-Bradley PLCs are engineered to scale with application needs. The company also produces a wide range of accessories, including

Allen-Bradley wiring devices, operator interfaces, and safety modules, all designed to integrate smoothly with their controllers.

Why Choosing the Right PLC Type Matters

Selecting the appropriate PLC type is critical for ensuring optimal system performance. The wrong choice can result in limited functionality, excess cost, or long-term inefficiencies.

Application-specific considerations

Each project has unique requirements. A small packaging machine doesn’t need the same controller as an entire production line. Important considerations include:

- I/O count: Number of input/output signals needed

- Processing speed: Required for time-sensitive operations

- Memory capacity: For storing logic, parameters, or recipes

- Expansion options: Possibility of adding modules later

- Communication support: To integrate with other systems or devices

A mismatch between the PLC’s capabilities and the actual needs can lead to wasted resources or system bottlenecks.

Common pitfalls in PLC selection

One frequent mistake is choosing a model based on familiarity rather than suitability. Other pitfalls include:

- Underestimating future expansion needs

- Ignoring compatibility with existing equipment

- Overlooking communication protocol requirements

- Choosing controllers with outdated hardware

Careful analysis during the selection phase helps prevent costly redesigns and downtime.

Overview of Allen-Bradley PLC Families

Allen-Bradley offers a range of PLC families, each targeting specific levels of complexity and scalability. Let’s take a closer look at the main series:

MicroLogix Series

The MicroLogix series is ideal for small automation tasks. These compact controllers are easy to install and program, making them a great choice for standalone machines or basic control systems. The MicroLogix lineup includes multiple models, such as 1000, 1100, 1200, 1400, and 1500. Each model increases in features, scalability, and communication support.

Applications include water well monitoring, irrigation systems, and simple production lines where cost efficiency matters but reliability cannot be compromised.

- I/O range: 10 to 256 points

- Communication: RS-232, Ethernet, DeviceNet

- Memory: Up to 64 KB

- Application: Basic packaging, water treatment skids, HVAC

They are budget-friendly yet powerful enough for many entry-level tasks.

SLC 500 Series

Though older, the SLC 500 series is still in operation in many facilities. It’s a modular system that supports mid-range control applications.

- Modular chassis-based design

- Up to 30 local and remote I/O modules

- Communication: DH+, Ethernet, Modbus

- Long field track record

Although officially designated as a legacy platform, the SLC 500 still operates in thousands of plants worldwide. Its ruggedness and modular architecture made it a long-time favorite across industries, such as automotive and bottling plants.

Many facilities continue to maintain and repair SLC 500 systems because replacement often requires complete revalidation and rewiring. This is where sourcing the right parts, such as reliable

AB boxes and enclosures, becomes crucial for minimizing downtime and avoiding full system overhauls.

Modules include analog and digital I/O, specialty communication modules, and memory expansion units. It's also known for its support of DH+ and DH-485 networking protocols.

CompactLogix Series

CompactLogix bridges the gap between small and high-end systems. It provides flexibility with modern features, such as integrated motion and data handling.

- Integrated safety and motion control

- Scalable memory and processor options

- Native support for Ethernet/IP

- Application: Mid-sized machines, OEM systems

CompactLogix bridges the cost-performance gap between MicroLogix and ControlLogix. Its architecture is based on the Logix 5000 platform, making it compatible with a unified programming environment (Studio 5000).

With native integration into Allen-Bradley HMIs and SCADA platforms, CompactLogix excels in packaging lines, printing presses, and material handling units.

ControlLogix Series

ControlLogix is the high-performance flagship PLC family designed for complex applications and plant-wide control.

- High-speed processing

- Large memory and modular architecture

- Redundancy and motion control

- Integrated safety and network features

Applications go beyond factories into offshore oil rigs, large water treatment plants, and multi-line manufacturing setups.

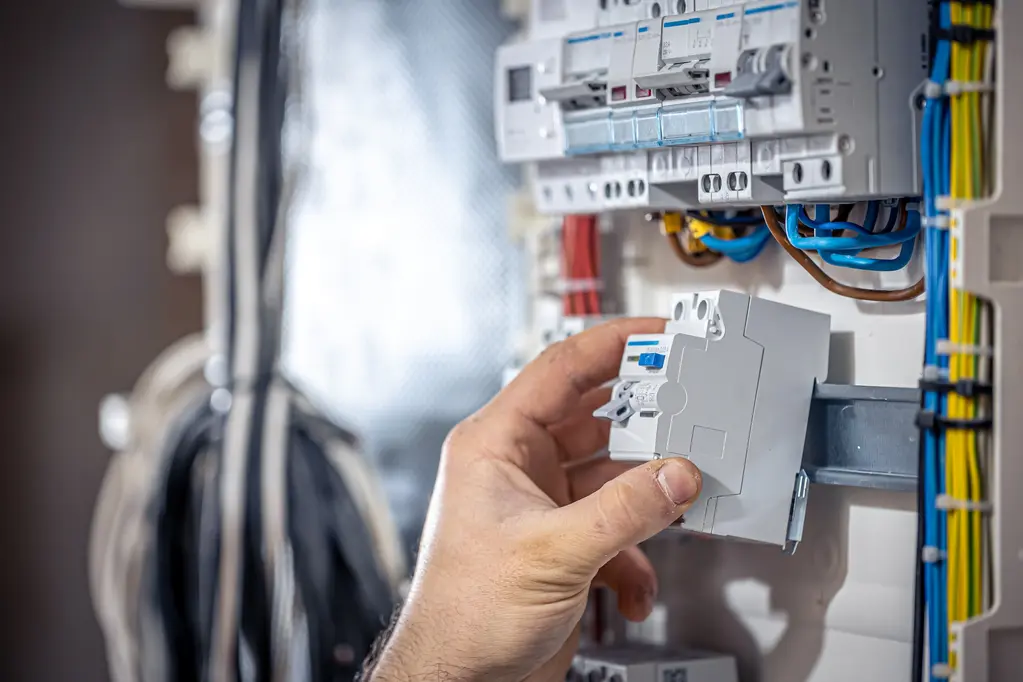

Reliable wiring is critical in these environments. That’s why plants often pair these PLCs with industrial-grade

wire and cables designed to withstand electromagnetic interference and temperature swings, following precise

PLC wiring diagrams to ensure correct installation and operation.

Pico and Nano Controllers

For extremely simple control needs, Allen-Bradley offers Pico and Nano-sized PLCs. These are designed for tasks such as lighting control, small pump systems, and simple sequential tasks.

- Very low I/O count

- User-friendly display

- Basic logic capabilities

They are an affordable solution for basic automation tasks in tight spaces.

Comparison of Allen-Bradley PLC Types

To better understand the difference between Allen-Bradley PLCs, here’s a side-by-side look at their features and typical uses.

Suitable Applications by PLC Type

- Food Processing: CompactLogix for ovens and mixers

- Water Treatment: MicroLogix for remote pump stations

- Automotive Assembly: ControlLogix for coordinated robotics

- Building Automation: Pico/Nano for lighting and elevators

- Energy Management: ControlLogix with advanced analytics

Matching the controller to your task ensures stable operations and long-term reliability.

Communication & Integration Capabilities

Modern automation relies on communication between controllers, sensors, HMIs, and enterprise systems. Allen-Bradley PLCs support multiple protocols, enabling system-wide coordination.

Ethernet/IP and other supported protocols

Ethernet/IP is the most common protocol used with Allen-Bradley controllers. It offers fast, real-time data transfer, diagnostics, and easy device discovery. Other protocols include:

- ControlNet

- DeviceNet

- Modbus TCP

- DH+ and DH-485

- Serial protocols (RS-232, RS-485)

This variety enables flexible integration with both legacy and modern equipment.

Integration with HMIs, SCADA, and industrial networks

All Allen-Bradley PLC types can connect with visualization systems. They integrate seamlessly with PanelView HMIs and FactoryTalk SCADA systems for:

- Real-time process monitoring

- Alarm management

- Historical data tracking

- Remote access and control

Additionally, they support OPC UA and MQTT for integration with IIoT systems and cloud platforms.

Choosing the Right Allen-Bradley PLC for Your Needs

Choosing the right model starts with clearly identifying your operational requirements. Here are key factors to consider.

Checklist of selection factors

- I/O Count – How many devices are you controlling?

- Speed – Does the process require fast response times?

- Environment – Harsh, outdoor, clean room, or standard?

- Connectivity – Required protocols or devices?

- Expandability – Will the system grow in the future?

- Power supply – Is 24VDC or 120VAC more suitable?

- Safety – Do you need SIL or safety-rated control?

For facilities with diverse requirements, modular systems like ControlLogix offer long-term flexibility.

Matching PLCs to industry types

- Consumer Goods – CompactLogix for labeling and packaging

- Oil & Gas – ControlLogix for compressor control and safety

- Water/Wastewater – MicroLogix for lift stations

- Pharma – CompactLogix for batch control

- Mining – SLC 500 in remote conveyor systems

Working with a trusted supplier like

BSP Automation ensures you receive support in identifying the right control system for your exact application.

Where to Buy Allen-Bradley PLCs and Components

Purchasing from authorized suppliers guarantees access to genuine hardware, technical documentation, and post-sale support. BSP Automation offers:

- A full selection of Allen-Bradley PLCs

- Original software and licensing

- Technical support and consultation

- Quick access to spare parts and accessories

Explore their dedicated section on

Allen-Bradley solutions to get started with your order.

Whether you're adding I/O modules, expanding your system, or replacing legacy components, BSP Automation offers everything from controllers to

Top PLC brands in one place.